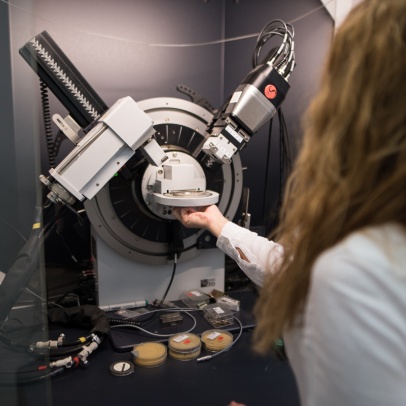

- X-ray Powder Diffractometer BRUKER D8 ADVANCE (Bruker AXS, Germany) with cobalt lamp, equipped with PDF 2 Release 2004 database.

- Raman Confocal Microscope XploRA™ (Horiba Jobin Yvon, France)

- UV-VIS Spectrometer CINTRA 303 (GBC Scientific Equipment)

- Cellometer Auto T4 (Nexcelom Bioscience LLC., USA) and Optical Microscope Olympus CX31 (Olympus)

- Optical Digital Microscope VHX-500 (Keyence Corporation, Japan)

- line-KBW growth chamber (E5.1) with adjustable illumination cassettes and RD3 microprocessor (Binder GmbH)

- Nicolet 6700 FT-IR Fourier Transform Infrared Spectrometer (Thermo Scientific, USA)

- Laminar flow box Steril Bio Ban Compact (Schoeller)

- Benchtop Autoclave Tuttnauer 3850 EL (Tuttnauer)

Molecular Modeling

Computer molecular modelling using force fields is an alternative to quantum-chemical calculations. The individual elements present in the model are parameterized by a set of variables (force field) with respect to the chemical environment of the element (atomic type). Thus, molecular modelling using force fields – molecular mechanics and time-parameter-involving molecular dynamics – does not directly account for electrons but simplifies the description of atoms on rigid spheres of a given diameter, mass, charge, etc., while bonds are described as springs of different lengths and stiffnesses. Despite these simplifications, molecular mechanics and dynamics are effective and commonly used tools for the study of nanomaterials. Moreover, this simplified approach makes it possible to work with models containing more than ten thousand atoms and, thus, brings the model significantly closer to a real sample. In addition to the possibility of finding the lowest potential energy of the studied system and the corresponding geometry of the structure, non-bonding interactions between individual components of the nanocomposite, mixture, solution, etc., can also be studied.

The Materials Studio modular modelling environment, which is used at the Nanotechnology Centre, VŠB-TU Ostrava, allows performing – in addition to molecular mechanical and dynamic calculations, for which various force fields are implemented (Universal, COMPASS, CVFF, PCFF, etc.) – other types of simulations too. These simulations include simulations of X-ray powder diffraction patterns or infrared spectra, the study of miscibility and docking calculations, prediction of potential polymorphs of a given compound or crystal shape depending on the structure and its surroundings, determination of the most suitable adsorption sites for a given adsorbent-adsorbate system, etc.

A significant advantage of the Materials Studio modelling environment is its fully visual and user-friendly 3D environment. The structural models can be built – automatically from source data or manually and further modified in various ways.

In addition to the preparation of input models for various types of simulations, this visual environment is used as a source of illustrative teaching materials, which helps students to better understand the structure of substances than that provided by classical 2D schemes. Work in the Materials Studio modelling environment is also a part of specialized lectures in the Master's study programme Nanotechnology.

In research, the molecular modelling is used in close cooperation with analytical methods, the results of which are supplemented and expanded by information either experimentally unattainable or very difficult to achieve.