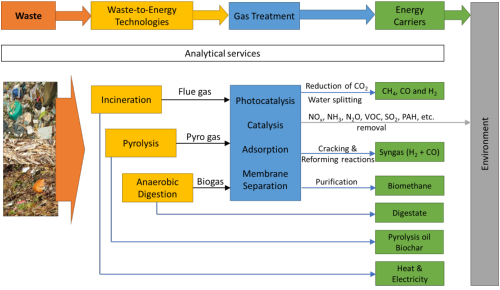

ENREGAT offers services and access to the core facilities and equipment enabling research in the following areas:

Waste incineration

-

combustion tests - incineration of waste, fuels and refuse derived fuels,

-

evaluation of environmental impacts of combustion processes,

-

evaluation of energy efficiency of combustion processes and proposal of measures for its increase,

-

evaluation of produced emissions from combustion processes, proposal of measures reducing emissions production,

-

determination of physical and chemical parameters of waste and fuels,

-

material utilization of slag and fly ash from combustion processes.

Optimization of energy and materials waste recovery by thermochemical processes

-

pyrolysis and catalytic pyrolysis of waste (polymers, biomass, and other solid organic hazardous waste) in laboratory batch or semi-batch reactor, microwave reactor or continuous screw reactor; consulting on the scale up of the process,

-

catalytic cracking and reforming of hydrocarbons with the purpose of syngas refinement,

-

research of the possibilities of pyrolysis products (gaseous, liquid and solid) utilization.

Anaerobic digestion

-

conversion of biowaste (e.g. agricultural and food biowaste, organic fraction of municipal solid waste) to biogas and digestate by dry or wetdigestion in (semi) continuous regime,

-

use of applied microbiology to perform the pre-treatment of raw material for lignocellulose degradation,

-

physical modelling, process controlling and scale up.

Technologies for gas treatment

-

reduction of greenhouse gases (N2O) emission by catalysis and photocatalysis,

-

photocatalytic reduction of CO2 to useful products (CH4, methanol),

-

hydrogen generation by photocatalytic water splitting,

-

abatement of other pollutants (NOx, VOCs, NH3, CO, SO2, PAH, etc.) by catalysis, photocatalysis and adsorption,

-

material design - tailored preparation and modification of the materials in desired forms (grains, thin films, monoliths, foams) by conventional and unconventional methods for catalysis, photocatalysis and adsorption,

-

catalytic cracking and reforming of hydrocarbons with the purpose of the syngas and hydrogen production,

-

mutual correlation of the physico-chemical properties of materials and their efficiency for pollutant removal, stability and selectivity,

-

physical and mathematical modelling from micro- to macro scale, i.e. structure, mechanisms and kinetics, transport phenomena, equipment.