At the laboratory of thermochemical processes, the focus of our research is on the valorization of wastes by thermochemical treatment. We perform both fundamental and applied research. Our research can be divided in two main parts.

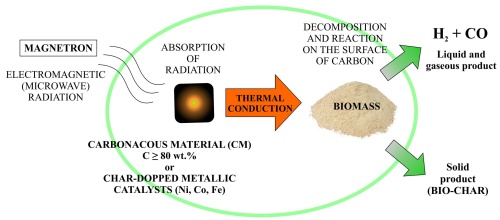

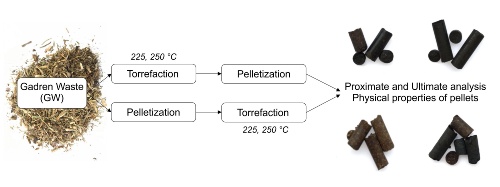

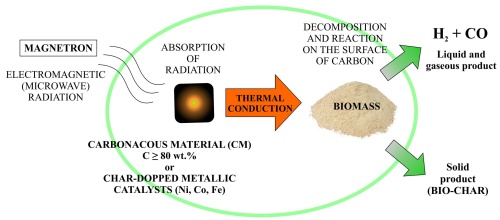

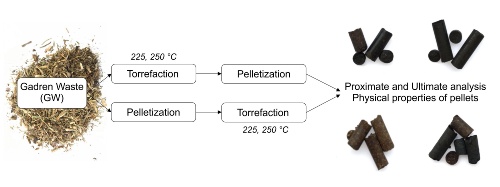

The first part deals with the processing of waste biomass with an aim to obtain products with a higher added value. We perform pyrolysis for the production of biochar, carbonization to produce activated carbon sorbents and torrefaction to obtain coal-like high-energy-density materials.

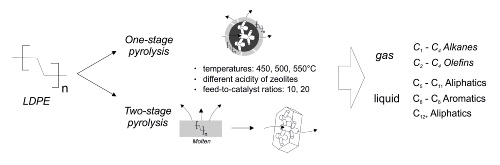

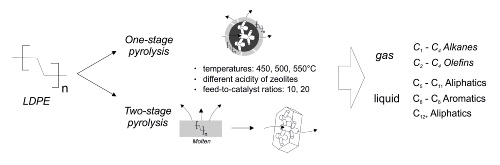

The second part of our research deals with the chemical recycling of waste plastics. Chemical recycling offers the possibility of transforming waste polymeric materials back to their original monomers or other valuable chemicals which can be used as feedstocks in chemical and petrochemical industries. At our laboratory, we carry out thermal and thermo-catalytic pyrolysis for the chemical recycling of waste plastics.

Last but not least, we deal with hydrogen production using the catalytic (dry and steam) reforming of waste gases emerging from thermochemical treatment of both biomass and waste plastics.

Research activities

- Waste management and recycling of solid and liquid wastes.

- Valorization of waste polymeric materials by thermal and thermo-catalytic treatment (Chemical Recycling).

- Sorbent production from waste carbonaceous materials for the adsorption of pollutants in air and water.

Basic equipment

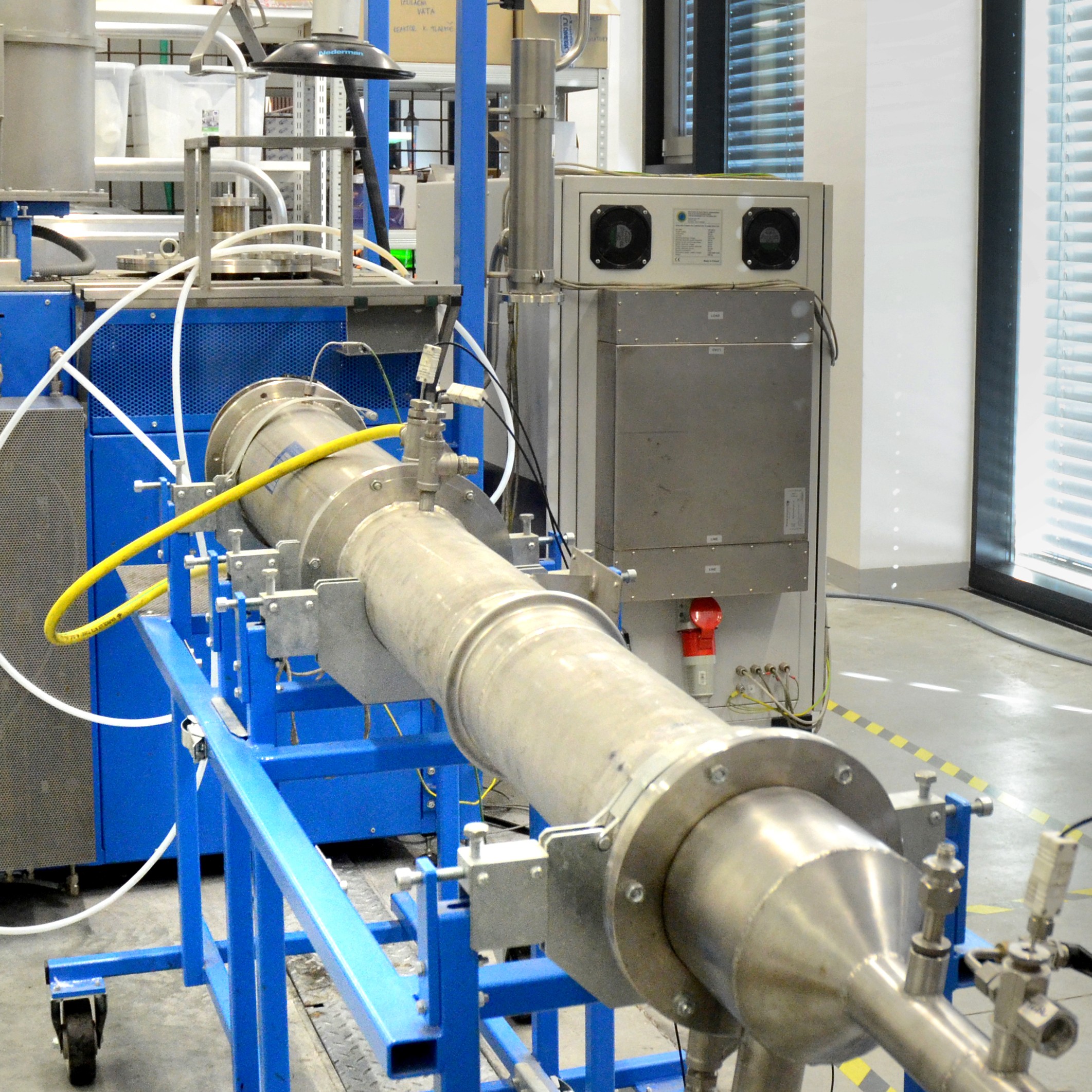

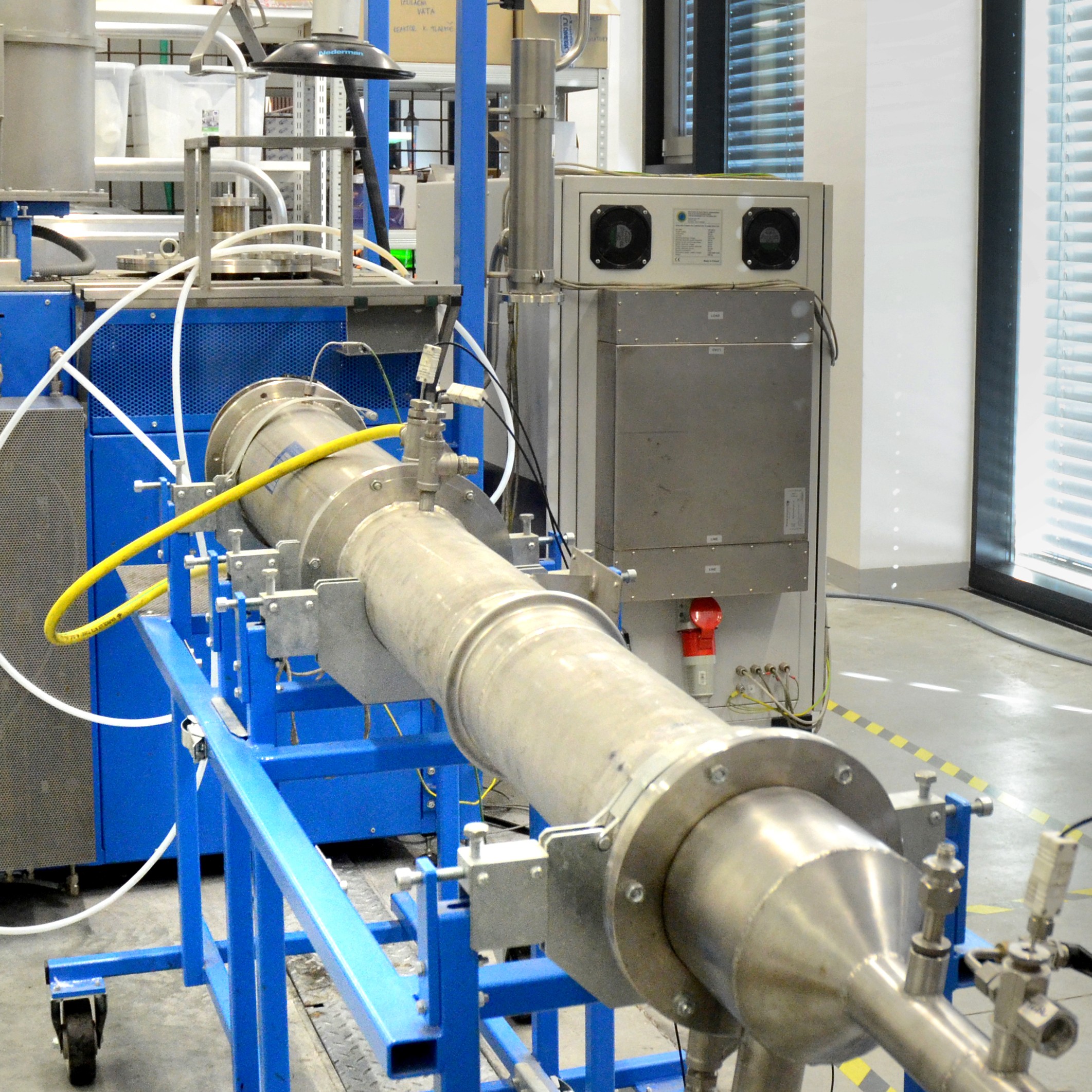

- Batch pyrolysis reactor (max. volume: 10 dm3, max temperature: 800-850 °C).

- Batch pyrolysis reactor (max. volume: 0.5 dm3, max. temperature 1000 °C).

- Pilot scale continuous pyrolysis unit (max. feed rate: 2 kg/h)

- Microwave reactor (power up to 1 kW).

- One and two stage test rigs for thermo-catalytic pyrolysis.

- Test rig for dry reforming of methane and/or pyrolysis vapors.

- Plasma (Gliding Arc) process module for VOC removal.

Offered services

- Material and energy balances for thermal treatment of biomass, general and hazardous wastes.

- Analysis of gaseous and liquids products resulting from waste treatment.

- Determination of water content by Karl Fischer titration.

Research team

Ing. Pavel Leštinský, Ph.D.

Dr.-Ing. Amer Inayat

Ing. Barbora Grycová, Ph.D.

Ing. Kateřina Klemencová, Ph.D.

Ing. Jana Vaštyl, Ph.D.

Ing. Jakub Korpas, Ph.D.

Dr. Subhasis Das

Ing. Jana Strakošová

Mgr. Rozálie Wdówková

Contact

Ing. Pavel Leštinský, Ph.D.

e-mail:

tel.: 00420 597 32 7330

mobil: 00420 608 917 261

|

|