This laboratory focuses on research in the area of oxidation processes in thermal treatment of waste. The laboratory is equipped with a thermal waste incinerator with an hourly capacity of 30kg of waste. The equipment is completed with a flue gas cleansing system, including both continuous and discontinuous emission monitoring of raw and treated gas. The configuration of the devices allows a wide range of scientific experiments. The research infrastructure makes it possible to perform experiments aimed at observing environmental parameters and energy aspects of the waste incineration process. Another part of our research activities is focused on the investigation of solid combustion residue, its properties and evaluation of how this residue may be used.

Research activities

- Increasing the efficiency of combustion processes within simultaneous reduction of negative impacts on the external environment.

- Incineration of waste with specific parameters (high humidity, high calorific value, content of risk components, etc.).

- Evaluation of the methodology for determination of heat efficiency of furnace for waste incineration.

Basic equipment

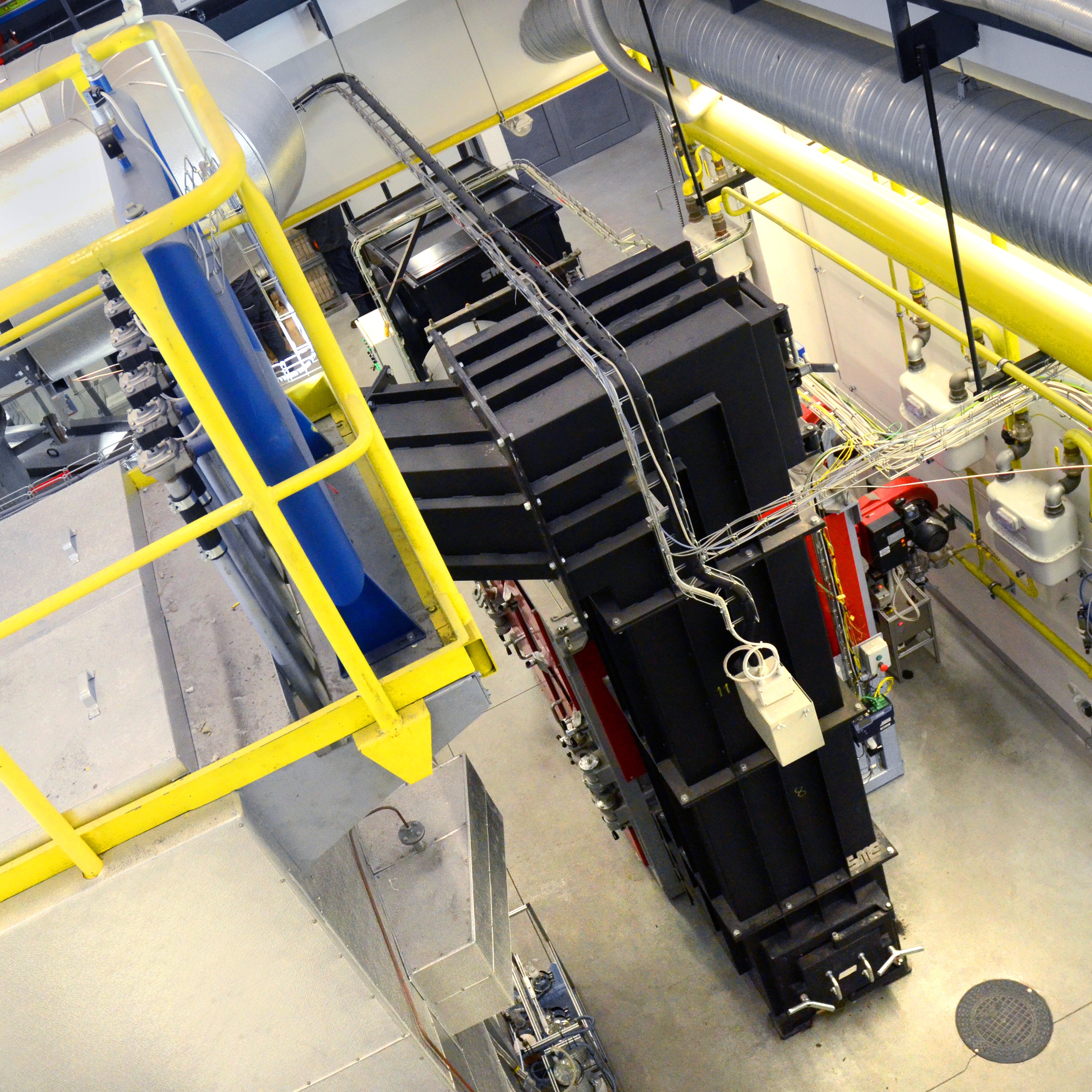

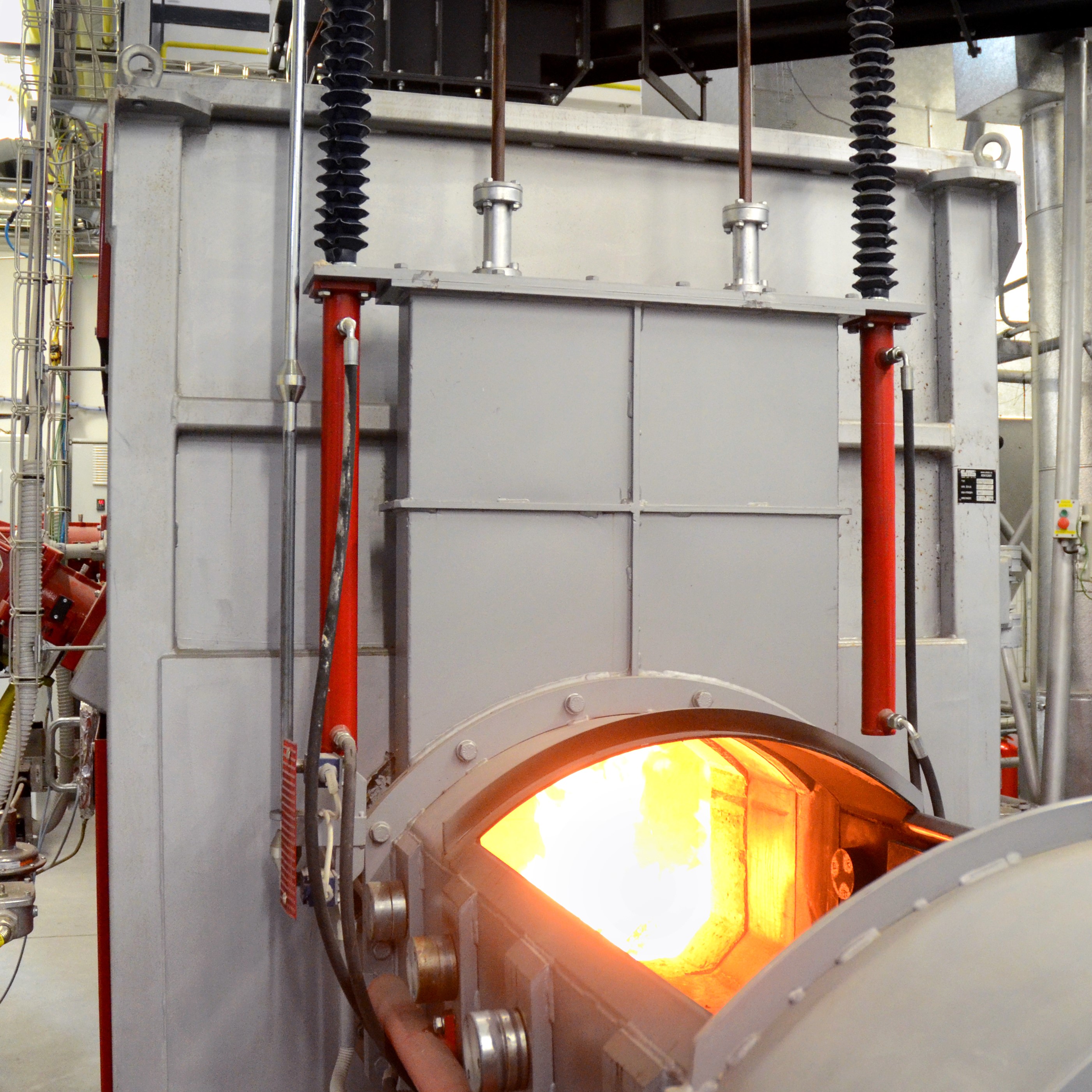

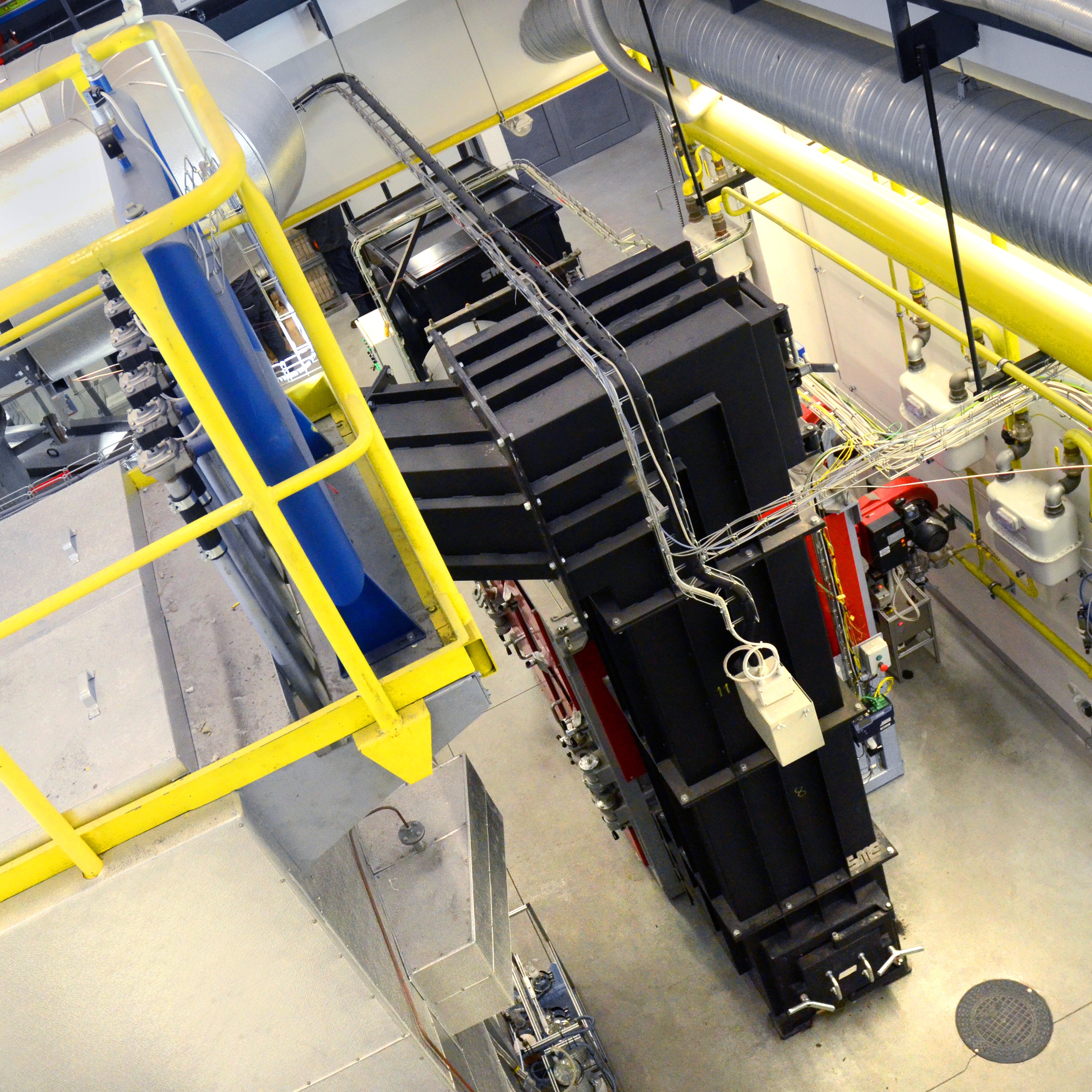

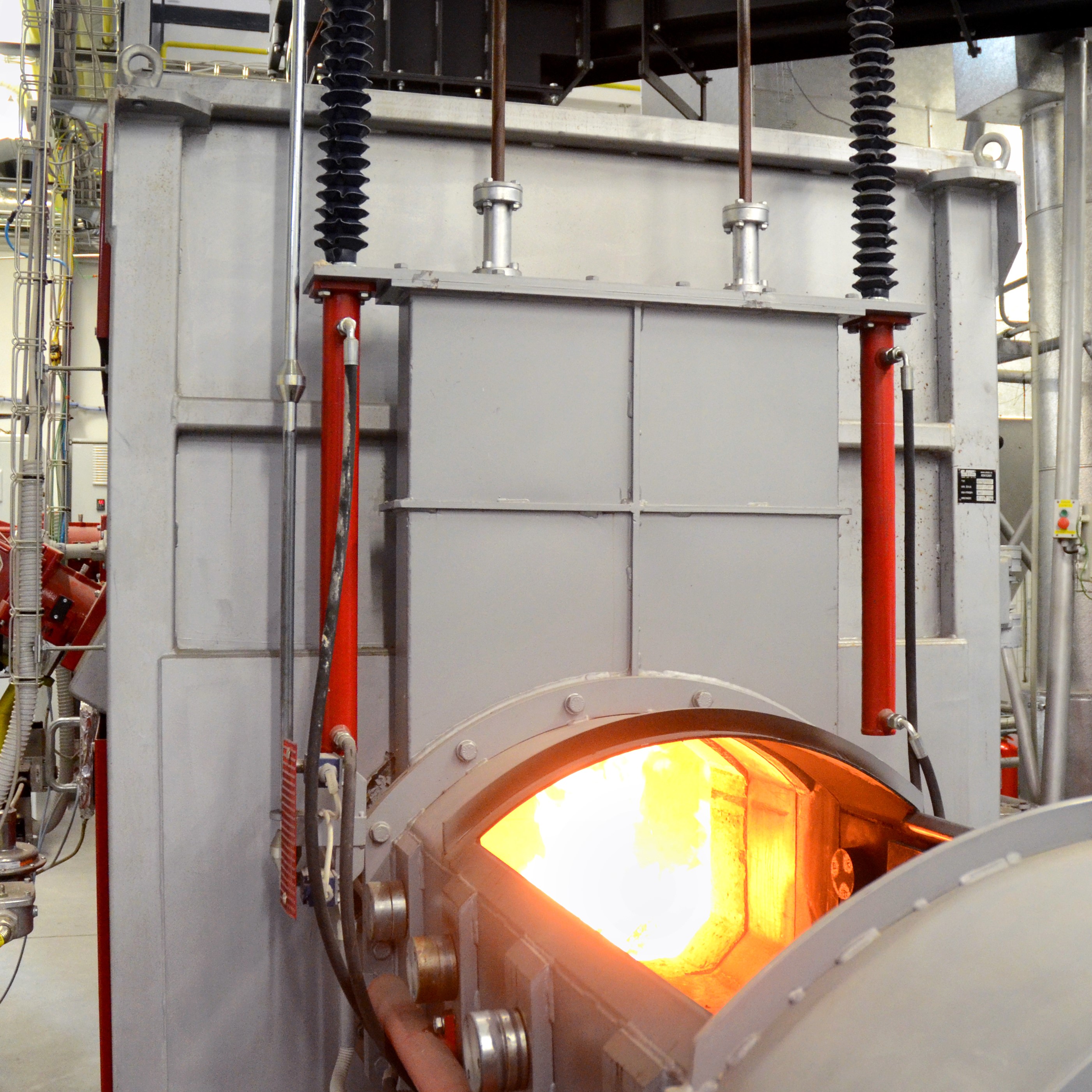

- Periodically operating combustion furnace with post-combustion chamber provided with burners for natural gas, maximum batch of 100 kg of waste incinerated in dependence on its specific weight. The premise is that time for combustion of this maximum amount will be about 6 hours.

- Continuously operating combustion furnace provided with post-combustion chamber with burners for natural gas is designed for a nominal capacity of 30 kg of waste incinerated per hour at its calorific value of 17 MJ.kg-1.Furnace allows to burn solid and liquid wastes.

- Filtration unit for flue gas cleaning by dry method in pilot plant scale designed to allow sampling of flue gases at different stages of combustion and thus allow research and optimization of the combustion process and cleaning. Parameters of the device: hose filter unit, filtration rate ≤ 13 mm / s, with the option to change the parameters of regeneration during its operation.

- Monitoring of pollutants in flue gas before and after the cleaning. The concentration of CO2, O2, CO, NO, NO2, N2O and SO2 can be monitored continuously, discontinuous sampling of flue gas for the measurement of solid particles, heavy metals, and other components is possible. Additional mobile equipment measuring CO2, O2 and CO in the flue gas allows monitoring the quality of the combustion process directly in the combustion chamber.

Research team

Ing. Jiří Burda

Ing. Jiří Fiedor, Ph.D.

doc. Ing. Marek Velička, Ph.D.

Contact

prof. Ing. Lucie Obalová, Ph.D.

e-mail:

tel.: 00420 597 32 7300

|

|