Catalytic decomposition of nitrous oxide – evaluation of pilot plant results

Lucie Obalová

Institute of Environmental Technology, VSB – Technical University of Ostrava, 17. listopadu 15, 70800 Ostrava, Czech Republic

e-mail: lucie.obalova@vsb.cz

Research of new catalysts for industrial application is a time-consuming and costly process. It is usually based on a large number of laboratory catalytic experiments, which provide feedback for the optimization of catalyst preparation procedure, chemical composition etc.

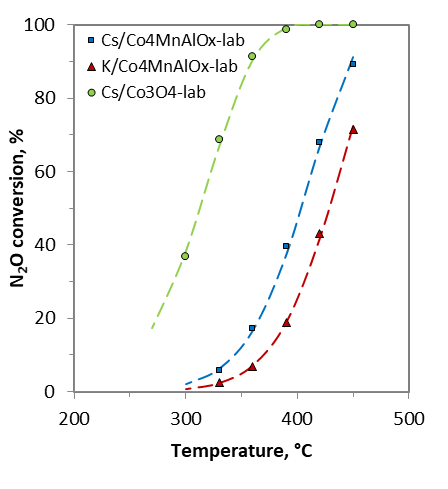

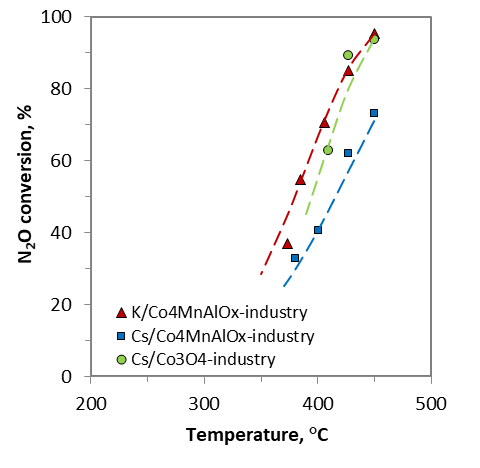

In presented lecture, three cobalt mixed oxide deN2O catalysts with optimal content of alkali metals (K, Cs) were prepared in large scale, shaped into tablets and tested in a pilot plant reactor connected at the bypassed tail gas from the nitric production plant downstream the SCR NOx/NH3. High N2O conversion of 75 – 90 % at 450 °C (GHSV=11 000 m3 mbed-3 h-1) was achieved. However, different activity order of commercially prepared catalyst tablets compared to laboratory prepared catalyst grains was observed (Fig. 1). This fact raised following questions:

(i) What are the reasons for different activity order of commercially prepared catalyst tablets compared to laboratory prepared samples?

(ii) Could our pilot-plant catalysts achieve higher activity (N2O conversions)?

(iii) What are the theoretical limits of N2O conversions over catalyst tablets, and how to approach them?

Catalytic experiments in kinetic regime, different characterization methods (XRD, TPR-H2, physisorption and chemical analysis), evaluation of kinetic parameters, internal effectiveness factor, and effective diffusion coefficients were utilized to answer these questions.

|

|

| a) | b) |

Fig. 1. N2O catalytic decomposition over: (a) laboratory prepared catalyst grains in simulated process condition (GHSV = 60 000 l kg-1 h-1); (b) commercially prepared catalyst tablets in real waste gas (VHSV = 11 000 l lbed-1 h-1)

Acknowledgements: The work was supported from ERDF OP RDE "Institute of Environmental Technology – Excellent Research" No. CZ.02.1.01/0.0/0.0/16_019/0000853. Experimental results were accomplished using Large Research Infrastructure ENREGAT supported by MEYS project No. LM2018098.